How are global chemical safely transported?

The safe transportation of global chemical involves multiple aspects, including compliance management, packaging technology innovation, transportation mode selection, and dynamic risk management.

Compliance management

The transportation of hazardous chemicals must strictly comply with relevant regulations and standards, such as the "Regulations for the Road Transport of Dangerous Goods" and the United Nations TDG classification standards. Enterprises need to ensure that the carrier holds a "Road Transport Business License" and dangerous goods transportation qualifications, and that the transport vehicles are equipped with electronic waybill systems that meet the standards. Special attention should be paid to the integrity of "one book, one signature", that is, the Safety Data Sheet (MSDS) should include both Chinese and English versions, and the hazard disclosure label should indicate the UN number, hazard category, and emergency measures.

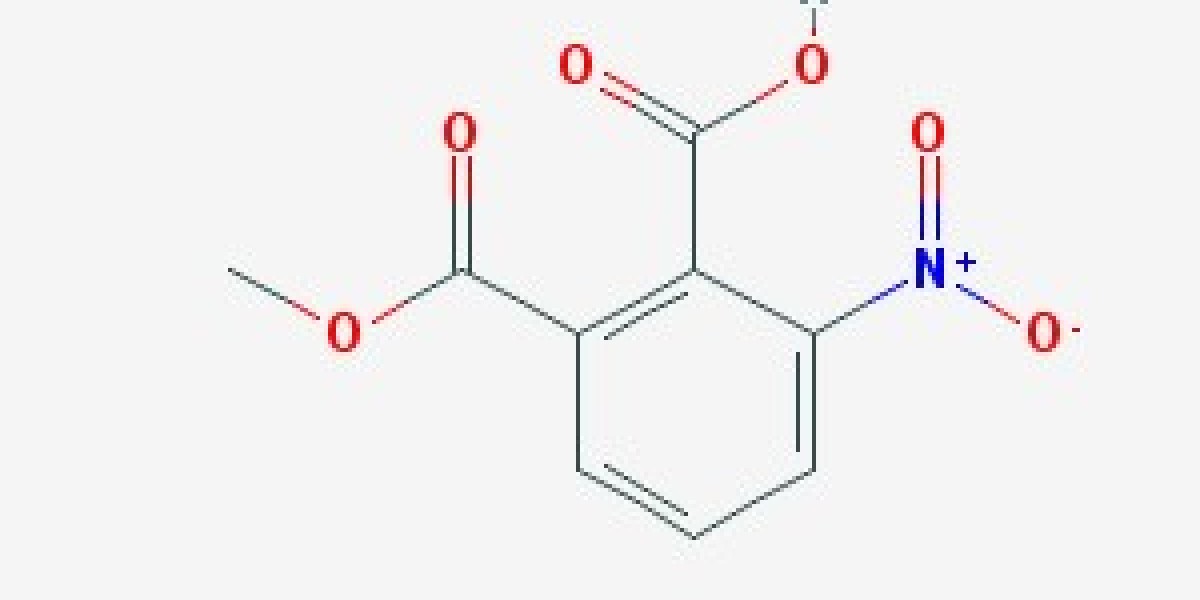

Packaging Technology Innovation

Packaging techniques vary depending on the characteristics of different chemicals. For example, when transporting explosive materials such as ammonium nitrate, a composite packaging of double-layer PE lining and galvanized steel drums should be used, and a 1.8-meter drop test should be passed. The transportation of hydrofluoric acid requires the use of special tank trucks with polytetrafluoroethylene inner tanks, and the tank wall thickness should not be less than 8mm. Gas raw materials need to be equipped with storage and transportation equipment with pressure self balancing devices to ensure structural stability in extreme environments. The packaging sealing of highly toxic substances such as acrylonitrile must meet the ISO 16101:2015 standard and be equipped with GPS positioning and tilt alarm devices.

Transportation mode selection

Road transportation: It is necessary to focus on checking the condition of vehicles, and tank trucks need to undergo NDT non-destructive testing every quarter. The tire tread depth should not be less than 3.2mm.

Railway transportation: Special tank containers with barrier and explosion-proof technology must be used and reported in advance.

Shipping by sea: Special attention should be paid to IMO classification management, such as maintaining a constant temperature of -13 ℃ and equipped with an independent emergency release system when transporting vinyl chloride monomer. Air transportation of liquid raw materials must comply with IATA DGR regulations, and the volume of a single package must not exceed 5L.

dynamic risk management

Establish an intelligent monitoring platform based on the Internet of Things, integrating temperature, pressure, and leakage sensor data to achieve 15 second level abnormal warning. For low flash point substances such as ether, an explosion-proof infrared thermal imaging device should be equipped to monitor static electricity accumulation. The emergency plan should include an evacuation plan within a radius of 3 kilometers, equipped with specialized leak prevention tools and neutralizing agents. Regularly conduct real-life drills to train drivers in their ability to handle unexpected situations.