In high-performance welding environments, precision and safety are non-negotiable. Whether you're operating a robotic weld cell or managing an automated assembly line, coolant system integrity is crucial for productivity and equipment protection. Yet one often-overlooked vulnerability can lead to catastrophic failure—A Leaking Shutoff Valve.

While small at first, valve leaks in coolant circuits can quickly evolve into major operational issues, causing unplanned downtime, damage to sensitive equipment, and even safety hazards. Understanding how and why these leaks occur—and how to detect them early—is essential for anyone responsible for maintaining industrial welding systems.

The Hidden Risk of a Leaking Shutoff Valve

Coolant systems play a vital role in robotic welding processes, dissipating heat and protecting torch equipment from thermal damage. Within these systems, shutoff valves control the flow of coolant to and from the weld head. When functioning properly, they regulate coolant flow based on system demands. However, when a valve begins to leak, it can allow coolant to escape or flow uncontrollably, even when it's supposed to be sealed off.

A leaking shutoff valve may result from several causes:

Wear and tear over time due to constant cycling in high-pressure environments

Thermal expansion or contraction, weakening seals and valve seats

Improper maintenance or misalignment in automated systems

Contaminants or particulates in the coolant fluid that damage internal components

The consequences can be severe. Coolant leaks lead to reduced flow to the weld head, which compromises weld quality and risks overheating. In the worst-case scenario, coolant may spray into the weld environment, threatening nearby electronics, causing short circuits, or creating safety hazards for operators.

Why Early Detection Matters

May facilities rely on routine visual inspections or timed maintenance schedules to check for valve integrity. But in high-volume or fast-paced production environments, that's often not enough. A small leak might go unnoticed until it becomes a much bigger—and more expensive—problem.

Early detection of a leaking shutoff valve provides several advantages:

Prevents damage to robotic welders and associated equipment

Avoids production line stoppages caused by coolant pressure loss

Reduces the risk of electrical short circuits or fire hazards from uncontrolled leaks

Cuts down maintenance and replacement costs by addressing issues before failure

Without real-time leak detection or automatic response systems in place, operators may only become aware of the issue after significant damage has occurred.

How to Prevent and Resolve Shutoff Valve Leaks

While prevention starts with proper valve selection and regular maintenance, it doesn't end there. Facilities must implement proactive monitoring systems that can identify leaks instantly, even during active production. Traditional manual methods can't compete with smart automation in terms of precision or speed.

Key strategies for leak prevention include:

Using high-quality valves suited to the specific operating pressure and temperature

Monitoring coolant flow rates and pressure in real time

Installing automated leak detection tools that shut off the coolant supply when leaks are detected

Performing fluid filtration and regular system flushes to reduce particulate contamination.

The most efficient solution, however, combines these best practices into one integrated, smart system.

Enter WeldSaver Technology: A Smarter Way to Protect Weld Cells

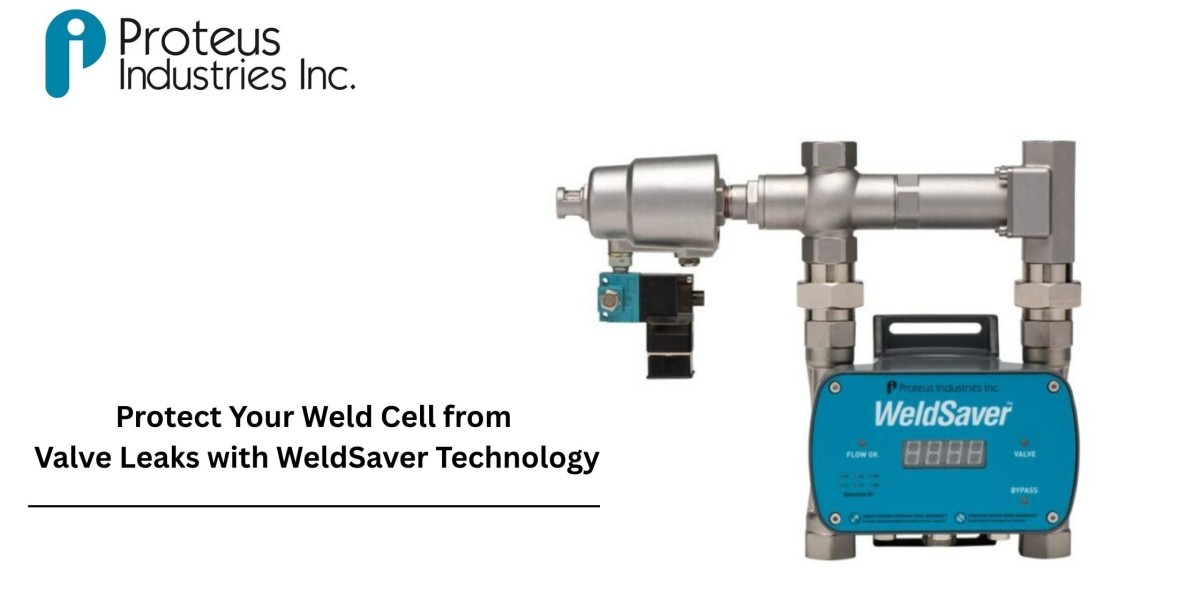

To address the critical need for reliable leak detection and automated shutoff control, Proteus Industries developed the WeldSaver 5 – Passport Series—an intelligent coolant monitoring solution designed specifically for robotic welding systems.

WeldSaver is more than just a flow sensor. It's an all-in-one system that continuously monitors coolant flow rate, temperature, and pressure in real time. If a leak is detected—whether from a leaking shutoff valve, burst hose, or other system failure—it triggers an immediate signal to halt welding operations and close the coolant circuit. This not only prevents further coolant loss but also protects the welder from thermal damage.

Key Benefits of WeldSaver:

✅ Real-time leak detection: Identifies anomalies the moment they happen, reducing response time to seconds

✅ Automatic shutoff: Instantly stops coolant flow when a leak is detected, minimising damage

✅ Equipment protection: Prevents overheating and coolant loss, safeguarding the welding torch and electronics

✅ Easy integration: Seamlessly fits into existing weld cell designs, including automated and robotic setups

✅ Diagnostic display: Includes local or remote monitoring options with digital interfaces for operators and maintenance teams

Whether you're overseeing a single weld cell or an entire automated line, WeldSaver gives you the confidence that your system is protected—even when human eyes aren't watching.

Why It Matters in Today's Welding Environments

Modern manufacturing demands uptime, accuracy, and efficiency. In such environments, even a minor leaking shutoff valve can derail timelines and inflate costs. With smart monitoring solutions like WeldSaver, manufacturers can reduce manual checks, catch issues early, and extend the life of their equipment.

More importantly, investing in preventative tools demonstrates a commitment to workplace safety and production reliability—two areas that directly affect your bottom line.

Final Thoughts

Leaking shutoff valves may seem like a minor issue, but in the world of robotic welding, they can lead to major disruptions. With the complexity and cost of modern weld systems, proactive leak detection is not just a convenience—it's a necessity.

By implementing advanced solutions like the WeldSaver 5 – Passport Series from Proteus Industries, you can ensure your coolant system is secure, your welds remain consistent, and your production line stays protected.