In today's energy and electronics industries, a High Frequency Transformer Factory plays a pivotal role in supplying components that enable efficient power conversion, compact device design, and reliable performance in demanding applications. From consumer electronics to renewable energy systems, these facilities ensure that specialized transformers meet both functional and environmental expectations.

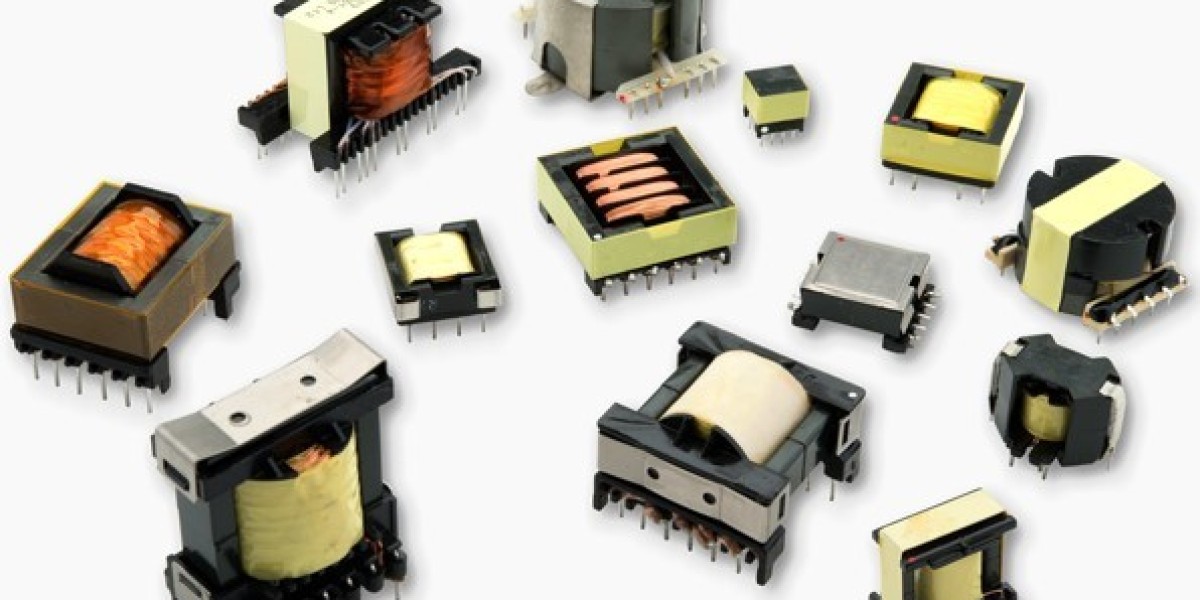

At the heart of such a facility lies advanced engineering. High frequency transformers differ from conventional designs by operating at elevated switching speeds, which allow for smaller sizes and lighter weights without compromising output. This capability makes them essential for devices such as chargers, inverters, and communication equipment. Factories producing these components must balance technical accuracy with cost efficiency, ensuring consistent results across different production scales.

The production workflow emphasizes precision at every stage. Beginning with the selection of high-quality core materials and winding wires, the process requires close control of insulation methods and assembly techniques. Each step is subject to rigorous checks, ensuring that transformers can operate reliably under high thermal and electrical stress. Automated machinery often works in tandem with skilled technicians to maintain consistency while adapting to unique client requirements.

Customization is increasingly central to the role of these factories. Different industries demand transformers with tailored voltage ranges, winding configurations, and physical dimensions. For example, a unit used in solar inverters may prioritize thermal endurance, while one designed for telecommunications equipment may emphasize signal clarity and low interference. By offering flexible solutions, manufacturers strengthen long-term partnerships with their clients.

Sustainability has also become a defining focus. Many facilities are implementing energy-saving production methods, recycling excess materials, and improving workplace safety. Beyond meeting regulatory expectations, these initiatives reflect an awareness of the broader impact manufacturing can have on communities and ecosystems. Such responsibility adds value for customers who prioritize environmentally conscious supply chains.

Another area of significance is testing. High frequency transformers must undergo performance validation to ensure compatibility with diverse operating environments. This includes thermal tests, electrical endurance evaluations, and electromagnetic interference checks. By maintaining high standards, factories protect end-users from malfunctions and ensure products remain dependable in global markets.

Ultimately, the importance of these facilities extends beyond the production floor. They contribute to the seamless functioning of modern electronics, renewable energy adoption, and industrial automation. With each product, they supply not just a component but also confidence in performance and durability.

For further insights into transformer solutions and product details, visit https://www.nbcbdz.com/product/