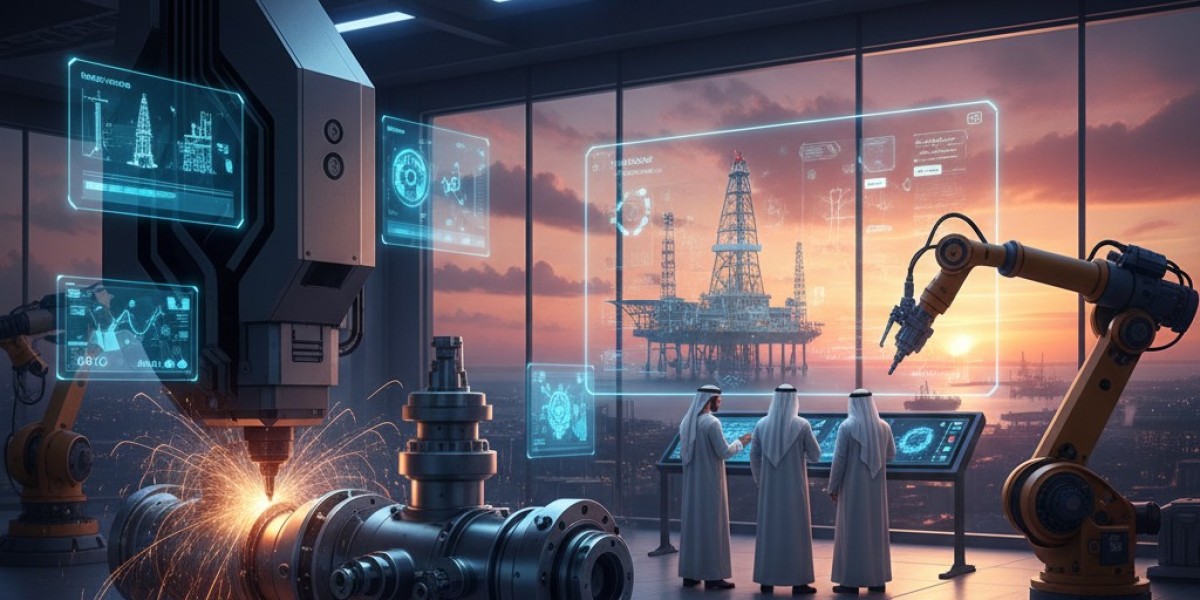

The oil and gas industry is a backbone of the Middle East’s economy, supporting energy needs, industrial growth, and technological development. Central to this sector’s efficiency and reliability is the use of high-quality oil and gas equipment. These tools and machines are designed to withstand extreme conditions, deliver consistent performance, and ensure the safety of operations. From drilling rigs to pumping systems, every piece of equipment is engineered to optimize productivity while reducing downtime and maintenance costs. A critical factor in achieving this performance is the integration of custom precision manufacturing in the Middle East. By leveraging advanced technologies and tailored design processes, manufacturers can create specialized components that meet the unique demands of regional oil and gas operations. This synergy between precision engineering and industry expertise ensures that companies can maintain competitiveness while adhering to international safety and efficiency standards.

The Role of Oil and Gas Equipment in Modern Energy Operations

Oil and gas equipment forms the foundation of exploration, extraction, transportation, and processing activities. High-quality machinery ensures that drilling operations are precise, pipelines operate smoothly, and storage and distribution systems remain secure. Modern equipment also incorporates sensors and monitoring technologies, enabling real-time data analysis for optimized performance. The Middle East, with its complex geological landscapes and large-scale production requirements, requires equipment that is both durable and adaptable. By using custom precision manufacturing in the Middle East, manufacturers can create components that are specifically designed for these challenges. This customization reduces wear and tear, enhances operational safety, and improves overall efficiency in energy production.

Advancements in Custom Precision Manufacturing

Custom precision manufacturing in the Middle East has revolutionized the production of oil and gas equipment. Advanced techniques such as CNC machining, laser cutting, and 3D printing allow manufacturers to produce components with tight tolerances and exceptional accuracy. This ensures that each piece of equipment performs flawlessly under demanding conditions. Moreover, precision manufacturing enables the development of specialized tools that address unique operational needs. For example, drilling equipment can be tailored for high-pressure environments, while pipeline components can be customized to resist corrosion from harsh chemicals. These innovations not only extend the lifespan of machinery but also contribute to safer and more efficient industrial practices.

Benefits of Integrating Precision Manufacturing in Oil and Gas

The integration of custom precision manufacturing in the Middle East into oil and gas operations offers several key benefits:

Enhanced Reliability: Components are engineered to precise specifications, reducing the likelihood of mechanical failure.

Increased Efficiency: Customized equipment operates optimally in specific environments, saving energy and time.

Cost-Effectiveness: Reduced downtime and longer equipment life lead to lower maintenance and replacement costs.

Safety Compliance: Precision-engineered parts help meet stringent industry safety standards, minimizing operational risks.

Through these advantages, oil and gas companies can maintain high productivity while ensuring the safety and sustainability of their operations.

Key Components and Equipment Manufactured

The range of oil and gas equipment produced through precision manufacturing is extensive. Key examples include:

Drilling rigs and drill bits: Engineered for strength and durability under extreme conditions.

Valves and pumps: Custom-designed for optimal flow control and pressure management.

Piping and storage solutions: Manufactured to resist corrosion, pressure fluctuations, and chemical exposure.

Monitoring and control systems: Precision-engineered for accuracy in detecting operational anomalies.

By tailoring these components through custom precision manufacturing in the Middle East, companies gain the flexibility to address site-specific challenges while maximizing productivity and safety.

The Future of Oil and Gas Equipment in the Middle East

The future of oil and gas equipment is closely linked to innovation in custom precision manufacturing in the Middle East. With increasing demand for energy efficiency, sustainability, and operational safety, manufacturers are investing in smart technologies and automation. Advanced sensors, AI-driven analytics, and robotics are being incorporated into equipment design to further enhance performance. Additionally, there is a growing emphasis on environmentally responsible production. Precision manufacturing allows for the development of eco-friendly components, reducing waste and energy consumption. This approach aligns with global trends toward sustainability while supporting the Middle East’s role as a leader in the energy sector.

Conclusion

The synergy between oil and gas equipment and custom precision manufacturing in the Middle East is transforming industrial operations across the region. Through tailored designs, advanced engineering, and precision production, companies are able to achieve higher efficiency, improved safety, and long-term reliability. As technology continues to evolve, the integration of innovative manufacturing solutions will remain crucial for sustaining the growth and competitiveness of the Middle East’s energy industry. By investing in precision-engineered equipment, businesses can ensure operational excellence while addressing the unique challenges of modern oil and gas production.

FAQs

1. What is the importance of oil and gas equipment in the Middle East?

Oil and gas equipment is essential for exploration, extraction, transportation, and processing. It ensures efficiency, safety, and reliability in operations across the region’s complex industrial landscape.

2. How does custom precision manufacturing benefit oil and gas operations?

It allows manufacturers to produce components with high accuracy and tailored specifications, increasing efficiency, reducing downtime, and ensuring compliance with safety standards.

3. Which oil and gas equipment is commonly produced using precision manufacturing?

Commonly produced equipment includes drilling rigs, valves, pumps, pipelines, storage solutions, and monitoring systems designed for specific operational requirements.

4. What technologies are used in custom precision manufacturing in the Middle East?

Technologies include CNC machining, laser cutting, 3D printing, robotics, and advanced sensors to ensure high-quality, accurate, and durable components.

5. What is the future trend of oil and gas equipment manufacturing?

The future focuses on smart and automated equipment, eco-friendly components, AI integration, and precision engineering to enhance efficiency, safety, and sustainability in the industry.