Optimizing Web Handling Performance with a Reliable Banana Roller Supplier

A dependable Banana Roller supplier plays a crucial role in modern manufacturing, especially for industries that rely on precise web guiding and wrinkle elimination during material processing. These rollers are engineered with a bowed structure that uniformly distributes tension across materials like film, foil, textiles, and paper, improving the overall efficiency and quality of production lines.

Banana rollers—also known as bowed rollers—are critical in preventing creases, bubbles, or overlapping in continuous web-based processes. Their value lies in their ability to manipulate material tension without physical contact adjustments, reducing waste and ensuring consistency across long production cycles. For companies dealing with flexible materials, investing in a well-designed banana roller is essential for maintaining quality standards.

Understanding the Function and Structure of Banana Rollers

Banana rollers function through a specific geometry: a fixed or adjustable bow in the shaft. This bow creates differential surface speeds across the roller, gently stretching the material laterally. The result is a flattening effect that removes wrinkles and stabilizes the web without damaging it.

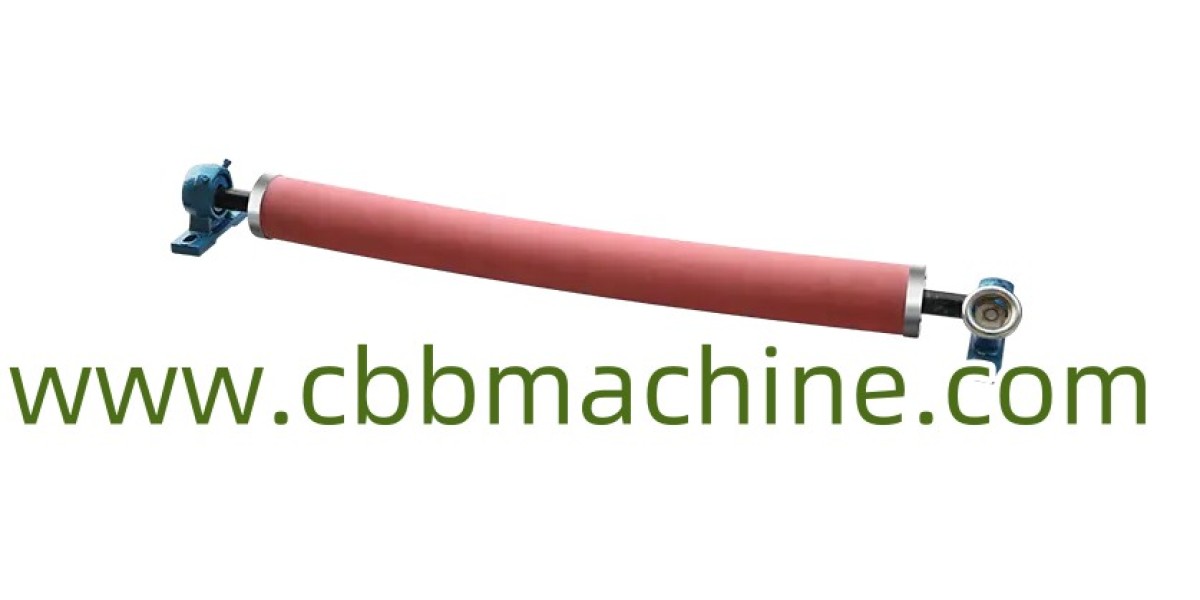

Key components of banana rollers typically include:

Shaft: Usually made of steel or aluminum for strength and reduced weight.

Covering: The outer surface, often rubber-coated, provides friction and resilience.

Bearings and Mounts: These ensure smooth rotation and alignment with the processing line.

Adjustment Mechanisms: Allow changes to the bow angle for different applications.

When manufactured to high precision, banana rollers offer long service life, require minimal maintenance, and significantly contribute to reducing downtime in production.

Customization in Banana Roller Design

A high-quality Banana Roller supplier often offers customization options that allow buyers to tailor the roller to specific material types, machine speeds, and environmental conditions. Depending on the application—whether it’s packaging, coating, printing, or laminating—the roller diameter, length, material type, and covering can be adapted to ensure optimal performance.

Customizable banana rollers can be produced with different:

Bow angles to suit varying web widths.

Surface materials to handle sensitive films or abrasive sheets.

Weight balances for high-speed applications.

Mounting options for specific machine models or configurations.

This flexibility allows businesses to enhance compatibility between the roller and the existing processing system, leading to greater production accuracy and less waste.

The Role of Precision in Manufacturing

For industries relying on high-speed continuous web handling, even minor imperfections in roller design can lead to significant losses. A competent Banana Roller supplier understands that the precision of bow radius, surface finish, and shaft alignment directly affects production output.

Suppliers who follow strict machining tolerances and perform quality inspections help reduce material slippage, edge folding, and tension inconsistencies. High-precision rollers also extend the service life of downstream components by minimizing mechanical strain during web transport.

Incorporating feedback from industrial users, suppliers often update their roller designs to improve functionality and fit in diverse industrial setups. This customer-focused development cycle enhances the long-term value of the machinery investment.

Choosing the Right Supplier for Operational Efficiency

When selecting a banana roller supplier, it's important to evaluate their ability to deliver consistent quality, offer technical support, and provide solutions tailored to specific industries. A good supplier doesn't just sell equipment—they offer insight into installation, adjustment, and maintenance procedures.

By choosing a reliable partner for banana rollers, manufacturers can:

Reduce unexpected downtime

Improve web alignment and product finish

Extend the lifespan of processing equipment

Enhance operator safety and confidence in the machinery

Whether for a new production line or a machinery upgrade, working with a skilled banana roller supplier ensures smoother operations and greater return on investment over time.